| 品牌 : | 蘇州道東 | 型號(hào) : | DG-GZX-1L |

| 加工定制 : | 是 | 包裝類(lèi)型 : | 瓶 |

| 工作原理 : | 常壓 | 適用對(duì)象 : | 果汁飲料,碳酸飲料,酒類(lèi)飲料,礦泉水、純凈水,酸奶,鮮奶,油類(lèi),護(hù)發(fā)用品,清潔、洗滌用品,醬類(lèi),口服液,藥水,液體酒精 |

| 適用行業(yè) : | 餐飲,食品,日化,醫(yī)藥,煙酒,化工 | 物料類(lèi)型 : | 液體 |

| 售后服務(wù) : | 整機(jī)一年保修 | 功率 : | 2.5KW |

| 外形尺寸 : | 10000*1500*2100mm | 灌裝頭數(shù) : | 6 |

| 灌裝量 : | 300-1000ml | 適用瓶高 : | 200mm |

| 適用瓶徑 : | 30mm | 生產(chǎn)能力 : | 1000瓶/H |

| 灌裝精度 : | 0.1% | 自動(dòng)化程度 : | 全自動(dòng) |

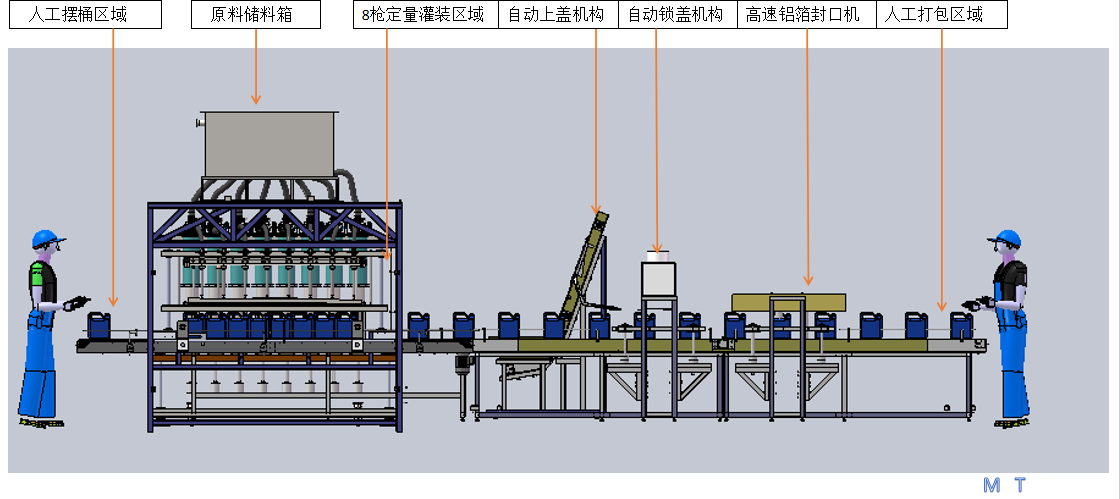

全自動(dòng)灌裝流水線(xiàn)DG-GZX-1L

系統(tǒng)特點(diǎn)及功能/Features

■ 控制系統(tǒng)采用 可編程控制器I/O PLC模塊等高端電氣配件制造,性能可靠、后期維護(hù)成本低;

The control system adopts the high-end electrical parts such as programmable controller I/O PLC module, which has reliable performance and low maintenance cost.

■ 密封及軟連接部分采用特氟龍制造,耐溶劑,耐酸堿,壽命長(zhǎng);

The sealing and soft connection uses Teflon, which is solvent resistant, acid and alkali resistant and has long service life.

■ 系統(tǒng)采用兩段式大、小料可調(diào)灌裝方式,提高了準(zhǔn)確度及生產(chǎn)能力;

The system adopts two-stage adjustable filling mode for the large and small materials, which improves the accuracy and productivity.

■ 目標(biāo)量自由設(shè)定,適應(yīng)多種重量范圍的定量灌裝;

The filling quantity can be set freely, which is suitable for quantitative filling in various weight ranges.

■ 全觸摸屏英文動(dòng)畫(huà)操作,全示教模式操作引導(dǎo)、可顯示目標(biāo)量、灌裝量、桶數(shù)、累計(jì)量等信息;

Full Touch Screen is English Animation Operation, Full Teaching Mode Operation Guidance, Display Target Quantity, Filling Quantity, Bucket Number, Cumulative Quantity and so on.

■ 系統(tǒng)采用全英文向?qū)讲僮鳎洃浌ぷ鹘M參數(shù)、及配方。醉大存儲(chǔ)100組參數(shù)、。

The system uses all-English guided operation to memorize working group parameters and formulas. Maximum storage of 100 sets of parameters,.

■ 設(shè)備可擴(kuò)展以太網(wǎng)接口/DP/NET接口,方便后期工廠(chǎng)數(shù)據(jù)集中控制與集成監(jiān)控。

The device can extend the Ethernet interface/DP/NET interface to facilitate centralized control and integrated monitoring of factory data in the later stage.

基本參數(shù)

■ 灌裝物料名稱(chēng): 脂、溶劑、涂料、油漆等。

■ 包裝重量:0.5-1KG

■ 醉小感量:10g

■ 灌裝誤差: 0.2%

■ 灌裝速度:1000-1500pcs/h(關(guān)聯(lián)人工上桶操作速度,及供料速度)

■ 控制方式:3擋控制(快、中、慢)

■ 灌裝方式: 液面上

■ 秤臺(tái)尺寸:定制

■ 灌裝頭: SS316L不銹鋼及特氟龍

■ 結(jié)構(gòu)材質(zhì): SUS304不銹鋼

■ 滾筒材質(zhì):復(fù)合不銹鋼

■ 管路壓力:0.2-0.6MPa(與料性有關(guān))。

■ 物料接口:DN40法蘭,可指定(物料及供料后端管道由貴方提供)

■ 氣源接口:用戶(hù)提供8mm氣管接頭,用于快速接頭連接

■ 使用電源:AC220/50Hz(用戶(hù)提供至機(jī)器一側(cè))

■ 使用氣源:0.4-0.8Mpa(用戶(hù)提供至機(jī)器一側(cè))

■ 使用溫度:-10℃-50℃

Basic parameters

Filling material name: grease, solvent, paint, etc.

Packaging weight: 30KG

Minimum Sensitivity: 10g

Filling accuracy: 0.2%

Filling speed: 100-150 pcs/h (Relevant to manual barreling operation speed and feeding speed)

Control mode: 3 gear control (fast, medium and slow)

Filling method: liquid surface

Scale size: 350*350 mm

Gun Head Pipeline: SS316L Stainless Steel and Teflon

Structural Material: SUS304 Stainless Steel

Drum Material: Composite Stainless Steel

Pipeline pressure: 0.2-0.6 MPa (related to material properties).

Material Interface: DN40 Flange, which can be specified (Material and back-end piping supplied by you)

Gas Source Interface: Users provide 8mm tracheal connectors for fast connection

Power supply: AC220/50Hz (user supplied to machine side)

Use of gas source: 0.4-0.8 Mpa (user supplied to machine side)

Temperature: - 10 -50.